- Home

- 3D Printer for Beginners

- How Do 3D Printers Work?

How Do 3D Printers Work? (Complete Beginner’s Guide to FDM Printing)

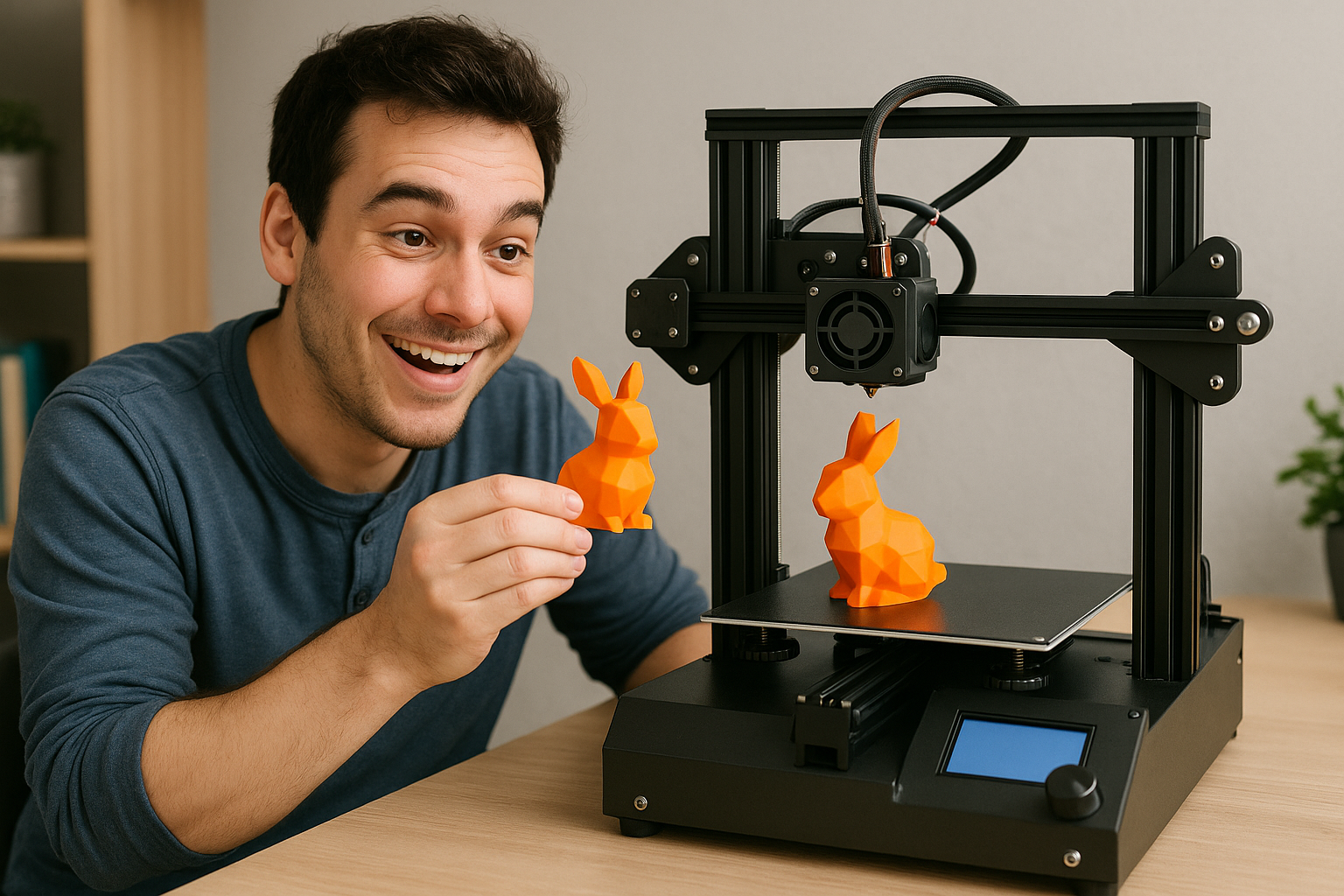

If you’ve ever seen a 3D printer at work, you probably know the feeling. You stare at this little machine moving back and forth, and slowly, as if by magic, something solid appears out of nothing.

The first time I saw it I thought, wait, how do 3D printers work?

How does it even know where to put the plastic?

So let’s sit down and talk it through.

By the end of this, you’ll be able to explain to anyone, in plain words, how do 3D printers work, and maybe you’ll feel a little itch to try it yourself.

What Is FDM 3D Printing?

Most people at home use a type of printer called FDM or FFF. That stands for fused deposition modelling, but don’t let the fancy name put you off. All it really means is that the printer melts a roll of plastic filament and lays it down in thin layers until it builds up a 3D shape.

Think of it like icing a cake. The nozzle is the piping bag, the cake is the flat plate it prints on, and the printer just keeps going, layer after layer, until you’ve got the full object sitting there.

The Core Components of an FDM 3D Printer

So what’s inside one of these printers? Well, not as much as you might think.

- You’ve got the spool, which is the roll of filament that feeds into the machine.

- Then there’s the extruder, which is like a motor that pushes the filament along a path towards the hot end.

- The hot end is where the real action happens. It has a heater that melts the plastic and a nozzle at the tip that squeezes it out.

- The nozzle is tiny, usually around 0.4 millimetres wide, so it can lay down fine lines of plastic.

- Underneath, you’ve got the build plate, which is just a flat surface, sometimes heated, to make sure the print sticks properly.

- The whole thing moves on rails and belts with little motors that control every movement in three directions.

- Oh, and don’t forget the fans, which blow air to cool the plastic just after it’s been laid down so it holds its shape.

That’s the hardware, but the printing actually starts on your computer. You either design something in CAD software or you grab a file from one of the online libraries. Once you’ve got the design, you can’t just send it straight to the printer.

Slice the model

You need to slice it first.

A slicer program takes the 3D model and cuts it into hundreds or even thousands of flat layers, then turns those into a file full of instructions called G-code. That file is basically a list of directions: move here, heat this much, extrude this much plastic. The printer just follows the script.

So let’s imagine you’re printing a small toy. You load the file into your printer, hit start, and the bed and nozzle begin to heat up. Once they’re at the right temperature, the extruder starts feeding filament into the hot end. The plastic melts and comes out the nozzle. The nozzle moves across the bed, laying down a thin line of plastic.

That’s the first layer.

Then the bed lowers slightly, the nozzle comes back, and it draws the second layer on top of the first. Bit by bit, your toy starts to grow.

It can take hours, depending on the size, but it’s kind of hypnotic to watch. You see something appear that didn’t exist before. Can you imagine showing that to someone from thirty years ago? They’d think it was science fiction.

Materials Used in FDM Printing

The materials you can use are another interesting part.

- PLA is the most common one. It’s easy to print, doesn’t warp much, and is perfect for beginners.

- Then there’s ABS, which is tougher and more heat resistant but can be a pain because it likes to curl up at the edges.

- PETG is a nice in-between option, strong and not too difficult to print.

- TPU is flexible, so you can make things like phone cases or gaskets.

- And then there are fun ones like wood-filled or glow-in-the-dark filaments.

Each one has its quirks, different printing temperatures, and different strengths.

Now, like anything, 3D printing isn’t always smooth. You’ll run into issues, and that’s normal.

Sometimes the print doesn’t stick to the bed and lifts up at the corners. Other times you’ll get stringy bits of plastic hanging between parts, like cobwebs. And clogs? Yeah, those happen too.

But here’s the thing, once you learn the basics of bed levelling, adjusting temperature, and cleaning your nozzle, you can solve most of these problems. It’s a bit like learning to cook. The first pancakes always burn, but after a while you know how to get it just right.

Common Applications of FDM Printing

So why would you want a 3D printer?

Well, people use them for all sorts of things. Hobbyists love them for making little gadgets, models, or even cosplay gear. Schools use them to teach kids about engineering and design, because it’s so satisfying to see your idea turn into a real thing you can hold. Businesses use them to prototype, saving time and money before committing to expensive manufacturing.

And at home, you’d be surprised how handy it is to make a custom hook, a replacement part for a toy, or even just a phone stand.

And things are only getting easier.

New printers are coming out with features like automatic bed levelling, so you don’t have to fiddle with screws to get the surface flat. Some can pause a print if you run out of filament, then carry on once you load a new roll. Others connect over Wi-Fi so you can send a job from your phone.

Materials are improving too, with stronger blends and even eco-friendly options. It feels like the hobby is moving from something niche to something almost mainstream.

At the end of the day, the answer to the question how do 3D printers work is simple.

How do 3d printers work?

They melt plastic and draw with it, one line at a time, until you have a finished object.

But when you dig into the details, you start to see why it’s so fascinating. The combination of hardware, software, and materials opens up so many possibilities. And the best part is you don’t need to be an engineer to enjoy it.

Anyone can set one up, tinker a bit, and start bringing ideas to life.

So if you’ve ever wondered how that little machine pulls it off, now you know. Next time you see one in action, you’ll be able to say, oh yeah, that’s the extruder feeding filament through the hot end, and the nozzle’s laying down the second layer right now.

Feels good when you can actually explain it, doesn’t it?

🛠 Share Your Experience

Tried this out, or have advice for other makers? Leave a comment and let’s learn together.